If I take manufacturer's app note or reference

design as base for a circuit stage in my hardware design, I don't implement it until I

understand how it works. This is simply because unless you can explain the

circuit to yourself and others, if it does not function as expected, you will have no idea how to

troubleshoot it or what changes to make adapt it to your needs.

Unless the circuit is trivial or already has

been worked out, I do two iterations of prototyping before committing to the

printed circuit layout - individual stages on a quick prototype boards (for DC

or low frequency

designs) and once they are proven to work, complete prototype on either wire wrap board or

point-to point solder perforated board. No need to reinvent a wheel here, but there is no

cut corners either. You've got to roll up your sleeves and try things out in

real life.

Take notes. If something does not work, don't leave it unsolved - the

problem will not go away on its own. Check out forums and similar design

references. Don't solder stuff keeping schematic in

your head to put it on paper afterwards - draw it first. Simulate your

circuit if applicable - it is far easier to

fix problems on paper or on the computer than have smoked ICs, burned PCB

traces

and other [avoidable] surprises.

Often you can trade hardware solution for the software code. Use what you are

most comfortable with. Everything else being about equal, my preference is

hardware, but this really depends. Software can do a lot but once in a while

you will have to write and debug hundreds of lines of code to accomplish

something a single filtering capacitor can accomplish. Don't afraid to do things "old

fashion way" - there is good reason for solutions that stood test of time.

Insulate loose test leads and small hand

tools to prevent damage if they fall onto powered

circuit and can short stuff. This is just small practical advise based on personal experience.

So, you settled on the concept of your circuit, hardware platform and defined

how you want your gadget to work. You captured proposed electrical schematic as a

first stab. Now what?

There are two types of circuit designs I usually faced with - either based on

a central processing unit and a lot of periphery and glue logic (usually digital

or mixed signal), or regular "distributed" type (as most analog designs) with input

on one side processing in the middle and output/indication on the right

side.

My usual sequence of

prototype assembly:

- - Power supplies. Without them nothing else can be tested.

You can use lab power supplies, but it is best to test HW with actual supply

to be used in final product.

- - Indication of any kind - to see what's going on. A single LED temporary hung on any

unused port flashing the error code will save you a lot of frustration, and that includes

debugging of the software. Granted, the software has to be written with this in mind -

with a bunch of diagnostics and cross checks, and critical info being outputted as the

code gets executed.

- If an LCD

display is used in the circuit, it gets wired and checked out next. Once

works, this becomes your output visualizer - you can spell out what is going

on rather than count flashes of a diagnostic LED.

- If your device has

a serial port, use it to connect to any terminal program, you can output a

lot of useful diagnostics to a PC.

- Sequence of wiring

other components is not very relevant, but I usually wire "independent"

stages first (such as relay drivers, RTC clocks, direct CAN ports, anything

not on a common internal SPI or other bus) so it all gets worked out while

the board is still least crowded. Bussed components get wired last.

- Of course the test code written for every stage being

tested better be as close to the final functionality as possible, so most routines will be

re-used in final software.

In case of analog design, sequence is not critical, but it makes

sense to start with the circuit stages that can be tested without anything

else, and add to them. I

often start with the "end" circuits such as LCD indication or a line driver. You

will need some type of signal generator to feed such circuit. If it is not

practical, start from the front end - sensor processing circuits or some

input conditioning circuits. The key is to add one active component at the time if possible (IC,

transistor), confirm it functions as expected and only then move on. Point is,

it is trivial to determine where the problem is if previous stage worked fine

but the new one doesn't. If you assemble whole thing that has never been

designed before, chances it will work right away are about the same as chances

that the software code you wrote won't need any debugging. And you may not

have good idea where to look for the problem.

Imagine wiring up entire circuit, similar to receiving a populated untested

PCB from the assembly house. You turn on the power for the first time and if

nothing works (provided, no smoke get out...) you don't know where to begin

troubleshooting. However, if, say, only CPU and serial UART is wired up

first, you test it and it doesn't work, there is nothing else on the board

to interfere yet, so you know exactly where to look for the problem. Once

UART stage is debugged, you wire up next one. If that does not work you know

it can no longer be UART, so no time wasted looking there. Moreover, use now

working UART to output diagnostic info to the PC via simple serial

connection. Fixing the problem is almost always trivial, the hardest part is

locating it. Thus ability to debug one stage at the time is great time

saver. IN case of CPI granted you will need keep writing supporting code to

at least toggle everything on the board.

For individual stages and prove of concept nothing beats traditional quick

prototyping board. These are good for frequencies from DC to a few hundred kHz and quite

limited as you can only place one row of ICs or other components between power rails.

You cannot test layout sensitive designs such as switching power supplies or for

instance some Op Amp circuits where capacitance of board's connecting strips

messes up feedback parameters. Nevertheless, these boards prove indispensible for quick verification of

parts specs, or if

something is functional on DC or low frequency level. Many modern semiconductor components

these days come only in SMT packages with their leads having increasingly small pitch. So in

order to prototype with them I mount them on a small adapter PCBs essentially converting them

to DIP packages. As a habit for a long time now, I add to all my PCB layout designs these small

break-away adapter boards - as many as will fit without increasing total PCB area. As a

result, over the years I've accumulated quite a few of them for many common SMT

packages such as SOT23, SOIC or TQFP. These adapters are handy not only to test SMTs on quick

prototyping boards, but they can be used on wire wrapping boards as well.

I'm always amazed when younger tinkerers stare at me when I mention

wire wrapping - turns out this unfortunately becoming lost art few people remember, let

alone using it. Creating circuits on wire wrapping boards is so

great that it was used in the past not only for prototyping of real complex circuits but

in final

products. Countless main frame computers with large back plane boards with edge connectors

used wire wrapped boards, which proved to be highly flexible and reliable - so

much so that electronics in early satellites was assembled that way. There is

still a lot info

on the web about the subject of micro-welds formed between wrapping wire and square gold

plated posts with sharp edges, so there is no need to repeat all this here. I just wanted

to mention that in my pro engineering design work flow wire wrapping is the second and last stage

of prototyping of complete systems before final circuit is settled and PCB artwork gets

developed1. The choice between wire wrap boards or perforated point to

point soldering boards,

depends on the final circuit complexity and amount of anticipated changes. On

wire wrap

boards it is trivial to make changes - unwrap wrong connections. This can be done

"in the field", away from quality solder stations. (Toys like cordless solder

irons do not count). Here are few photos of how it all comes together. Also wire

wrap boards are simpler to re-use - de-mounting al the components is not as

messy as for solder boards and does not require any cleanup.

This section is not meant to serve as tutorial how things should be

done. Everyone has own preferences, tools and habits. I just describe how I do it.

This workflow was evolved over many years and since it has never failed me, I see no reason to invent anything new. Here are few photos illustrating all above.

An example of point to point soldered prototype board - front view.

You can use it for relative simple spread out designs.

An example of point to point soldered prototype board - front view.

You can use it for relative simple spread out designs.

Same board - back side. This type of prototyping would

be too messy for a BMVCU project - not because of complexity of it, but amount

of anticipated re-soldering and changes. The insulation of standard Kynar wire

wrap wire is not very tolerant of the high temp and usually re-soldered 3-4

times gets damaged so the wire needs to be replaced. Also when you get to more than two layers of crossing wires,

it is very hard to unsolder a wire from the first layer without damaging its insulation.

With wire wrapping it is not an issue.

Same board - back side. This type of prototyping would

be too messy for a BMVCU project - not because of complexity of it, but amount

of anticipated re-soldering and changes. The insulation of standard Kynar wire

wrap wire is not very tolerant of the high temp and usually re-soldered 3-4

times gets damaged so the wire needs to be replaced. Also when you get to more than two layers of crossing wires,

it is very hard to unsolder a wire from the first layer without damaging its insulation.

With wire wrapping it is not an issue.

Example - final

prototype of EVision

gadget on a wire wrap board. This must be circa 2001. Large proto area allowed for multi-processor prototyping. This

type of prototyping will be used for BMVCU.

Example - final

prototype of EVision

gadget on a wire wrap board. This must be circa 2001. Large proto area allowed for multi-processor prototyping. This

type of prototyping will be used for BMVCU.

Same board - back side. Very simple to make - somewhat

tedious process requiring a lot of patience and attention, but very straight forward

one.

Same board - back side. Very simple to make - somewhat

tedious process requiring a lot of patience and attention, but very straight forward

one.

Complete modules mounted on DIP adapter - carrier board. This photo

shows a GPS module on top of the SMT-DIP adapter designed for TQFP IC packages.

PCB traces and SMT pads are actually not used here.

Complete modules mounted on DIP adapter - carrier board. This photo

shows a GPS module on top of the SMT-DIP adapter designed for TQFP IC packages.

PCB traces and SMT pads are actually not used here.

Mounting

tiny IC packages. This is about the smallest pitch IC I can handle - DFN leadless package

with 0.5 mm pitch and pads size 0.4 mm x 0.25 mm. soldering wires to such a pad by hand is

a challenge. You cannot use typical AWG 30 wire wrap wire for this, it is too stiff and

will break away the IC solder pad if you bend the wire. On this photo the IC

body is secured in a blob of

hot glue and the lead wires are not soldered to the adapter PCB yet. Avoid QFN

packages if you can!

Mounting

tiny IC packages. This is about the smallest pitch IC I can handle - DFN leadless package

with 0.5 mm pitch and pads size 0.4 mm x 0.25 mm. soldering wires to such a pad by hand is

a challenge. You cannot use typical AWG 30 wire wrap wire for this, it is too stiff and

will break away the IC solder pad if you bend the wire. On this photo the IC

body is secured in a blob of

hot glue and the lead wires are not soldered to the adapter PCB yet. Avoid QFN

packages if you can!

These are standard DIP adapter PCB with fork type

gold plated pins

specifically made for wire wrapping proto boards. They accommodate components whose leads

cannot be inserted into the board directly.

These are standard DIP adapter PCB with fork type

gold plated pins

specifically made for wire wrapping proto boards. They accommodate components whose leads

cannot be inserted into the board directly.

The SMT adapters as break away boards I

mentioned above. Loose pins and completed PCB example with SOIC package soldered

on it.

The SMT adapters as break away boards I

mentioned above. Loose pins and completed PCB example with SOIC package soldered

on it.

The

main CPU for this project (as mentioned above, the Microchip PIC32MX795F512L) mounted on

the special "Schmart

Board" I happen to have. It is very useful, so I'll make sure to add a few of

such adapters to my next PCB run.

The

main CPU for this project (as mentioned above, the Microchip PIC32MX795F512L) mounted on

the special "Schmart

Board" I happen to have. It is very useful, so I'll make sure to add a few of

such adapters to my next PCB run.

This handy gadget allows to identify discrete

semiconductor components - loose parts or while in circuit. Very handy for

reverse engineering and understanding/reconstructing schematics. You can read

more about some techniques doing in already mentioned

blog here.

This handy gadget allows to identify discrete

semiconductor components - loose parts or while in circuit. Very handy for

reverse engineering and understanding/reconstructing schematics. You can read

more about some techniques doing in already mentioned

blog here.

Completed

LCD display enclosure -3D printed. It is good enough to be placed on dash of the vehicle. The BMVCU enclosure will likely to be made the same way and fit in the

same spot in Audi where original VCU was mounted. This is natural location for it since

all the original interfacing comes to that, such as the pedal TPS'es I need access to.

Completed

LCD display enclosure -3D printed. It is good enough to be placed on dash of the vehicle. The BMVCU enclosure will likely to be made the same way and fit in the

same spot in Audi where original VCU was mounted. This is natural location for it since

all the original interfacing comes to that, such as the pedal TPS'es I need access to.

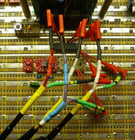

Beginning of the construction

on the wire wrapping board.

The CPU placed vertically in the middle of the wire wrapping board to have

access to the adapter board from both sides. Electrically

the wire wrap board is divided in two halves - 3.3V

powered section and 5V powered section. There are pre-routed PCB traces delivering power as

well as ground connection to the specific pins, so this is was convenient arrangement.

Beginning of the construction

on the wire wrapping board.

The CPU placed vertically in the middle of the wire wrapping board to have

access to the adapter board from both sides. Electrically

the wire wrap board is divided in two halves - 3.3V

powered section and 5V powered section. There are pre-routed PCB traces delivering power as

well as ground connection to the specific pins, so this is was convenient arrangement.

Photo from the top. I'll add more photos here as I move

along.

Photo from the top. I'll add more photos here as I move

along.

1

A notable exception to this is switching

power supplies - these are highly sensitive to the layout and often rely on

large copper areas to function properly. Usually I still manage to implement

them on the wire wrapping boards if they use one control IC, but if I have

complex isolated supply with multiple outputs on custom wound transformer, I

resort to tiny PCBs that can be made cheap. If in doubt about optimal layout, I

order step-and-repeat array with variations I can choose from.

Next -

everything I need to know about RLECs

Home of the project

This section is about designing and implementing

electronic

hardware in general, using as an example design of BMVCU for Audi in particular. The

is no magic why everything I design actually work - aside

general knowledge and accumulated experience, it's certain habits I developed

dealing with electronic circuits that come down to prototyping,

testing and then more testing. If someone asks me to suggest tips how to do a

good job designing electronics, I'd summarize them as follows:

This section is about designing and implementing

electronic

hardware in general, using as an example design of BMVCU for Audi in particular. The

is no magic why everything I design actually work - aside

general knowledge and accumulated experience, it's certain habits I developed

dealing with electronic circuits that come down to prototyping,

testing and then more testing. If someone asks me to suggest tips how to do a

good job designing electronics, I'd summarize them as follows: